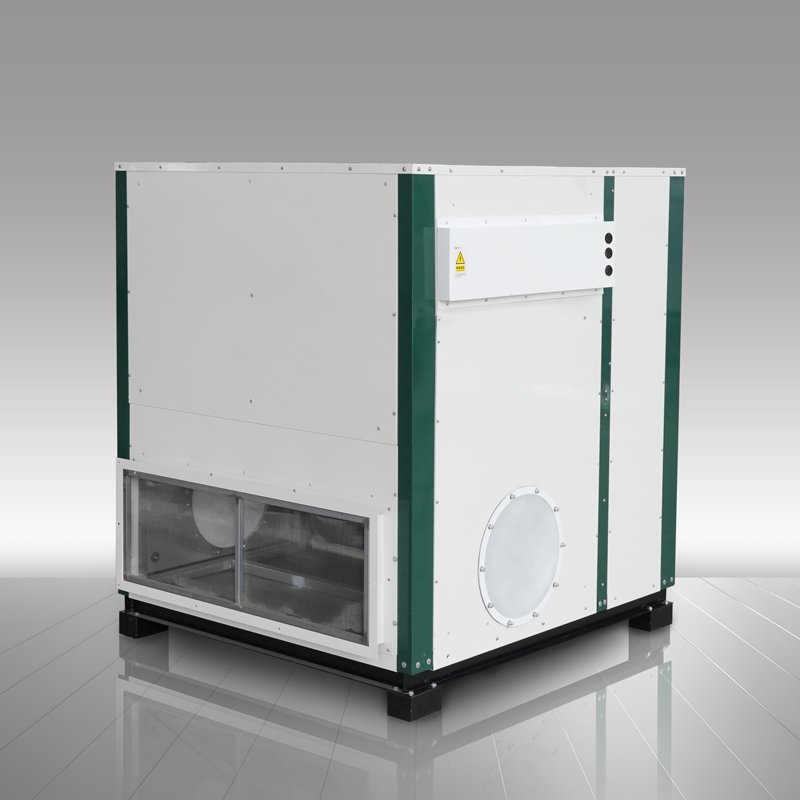

WesternFlag – Industrial double drum dryer

Short description

The double-drum dryer is a structural method independently developed by our company that uses biomass solid particle fuel as a heat source for drying operations. It has the advantages of high heat utilization, smokeless emissions, low operating costs, precise temperature control, and high degree of intelligence.

The double-drum dryer is developed to completely replace the drying bed and partially replace the mesh belt dryer. Due to the realization of energy recycling, it reduces more than half of the fuel consumption, changes the material from static to dynamic tumbling, can greatly improve the drying efficiency, ensure the uniformity of drying, and realize unmanned operation, reducing labor costs;

Parameters

1. Overall equipment dimensions: 5.6*2.7*2.8m (length, width and height)

2. Single-drum dimensions: 1000*3000mm (diameter*length)

3. Loading capacity: ~2000Kg/batch

4. Heat source selection: biomass pellet fuel

5. Fuel consumption: ≤25Kg/h

6. Temperature rise range in drying room: room temperature to 100℃

7. Installed power: 9KW Voltage 220V or 380V

8. Material: galvanized carbon steel or stainless steel in contact with materials or all stainless steel

9. Weight: Kg

Working principle Diagrams

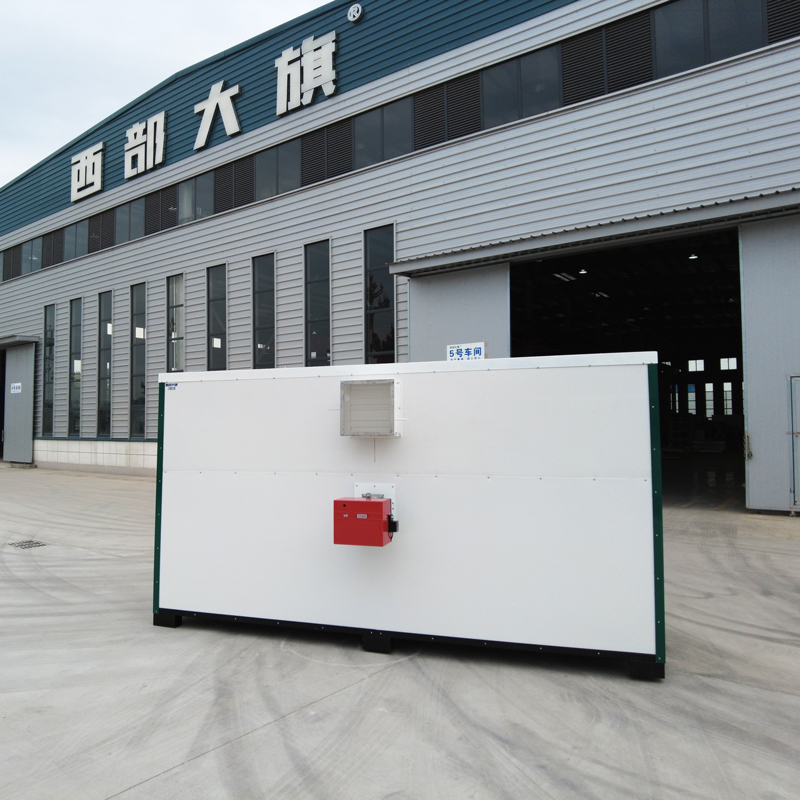

Real photo