WesternFlag – TL-4 Model Direct Burning Furnace With 3 Layers Sleeve

Short description

The TL-4 burningfurnace is designed with three layers of cylinders and utilizes fully burned natural gas to produce a high-temperature flame. This flame is mixed with fresh air to create the required hot air for various applications. The furnace employs fully automatic single-stage fire, two-stage fire, or modulating burner options to ensure clean output hot air, meeting the drying and dehydration needs for a wide range of materials.

External fresh air flows into the furnace body under negative pressure, passes through two stages to sequentially cool the middle cylinder and inner tank, and then enters the mixing zone where it is fully combined with the high-temperature flame. The mixed air is then extracted from the furnace body and directed into the drying room.

The main burner ceases operation when the temperature reaches the set number, and the auxiliary burner takes over to maintain the temperature. If the temperature drops below the set lower limit, the main burner reignites. This control system ensures efficient temperature regulation for the desired applications.

Advantages/Features

1. Simple structure and easy installation.

2. Small air volume, high temperature, adjustable from normal temperature to 500℃.

3. Stainless steel high temperature resistant inner tank, durable.

4. Automatic gas burner, complete combustion, high efficiency. (After setting up, the system can control the ignition+cease fire+temperature adjust automatic).

5. The fresh air has a long stroke that can fully cool the inner tank, so the outer tank can be touched without insulation.

6. Equipped with high temperature resistant centrifugal fan, large pressure center and long lift.

Specifications

| Model TL4 | Output heat (×104Kcal/h) |

Output temperature (℃) |

Output air volume (m³/h) |

Weight (KG) |

Dimension(mm) | Power (KW) |

Material | Heat exchange mode | Fuel | Atmospheric pressure | Traffic (NM3) |

Parts | Applications |

| TL4-10 Natural gas direct burning furnace |

10 | Normal temperature to 350 | 3000--20000 | 480 | 1650x900x1050mm | 3.1 | 1. High temperature resistant stainless steel for inner tank2. Carbon steel for middle and outer sleeves | Direct combustion type | 1.Natural gas 2.Marsh gas 3.LNG 4.LPG |

3-6KPa | 15 | 1. 1 pcs burner2. 1 pcs induced draft fan3. 1 pcs furnace body4. 1 pcs electric control box | 1. Supporting drying room, dryer and drying bed.2, Vegetables, flowers and other planting greenhouses3, Chickens, ducks, pigs, cows and other brooding rooms4, workshop, shopping mall, mine heating5. Plastic spraying, sand blasting and spray booth6. Rapid hardening of concrete pavement7. And more |

| TL4-20 Natural gas direct burning furnace |

20 | 550 | 1750x1000x1150mm | 4.1 | 25 | ||||||||

| TL4-30 Natural gas direct burning furnace |

30 | 660 | 2050*1150*1200mm | 5.6 | 40 | ||||||||

| TL4-40 Natural gas direct burning furnace |

40 | 950KG | 2100*1300*1500mm | 7.7 | 55 | ||||||||

| TL4-50 Natural gas direct burning furnace |

50 | 1200KG | 2400*1400*1600mm | 11.3 | 60 | ||||||||

| TL4-70 Natural gas direct burning furnace |

70 | 1400KG | 2850*1700*1800mm | 15.5 | 90 | ||||||||

| TL4-100 Natural gas direct burning furnace |

100 | 2200KG | 3200*1900*2100mm | 19 | 120 | ||||||||

| 100 And above can be customized. |

Working Schematic Diagram

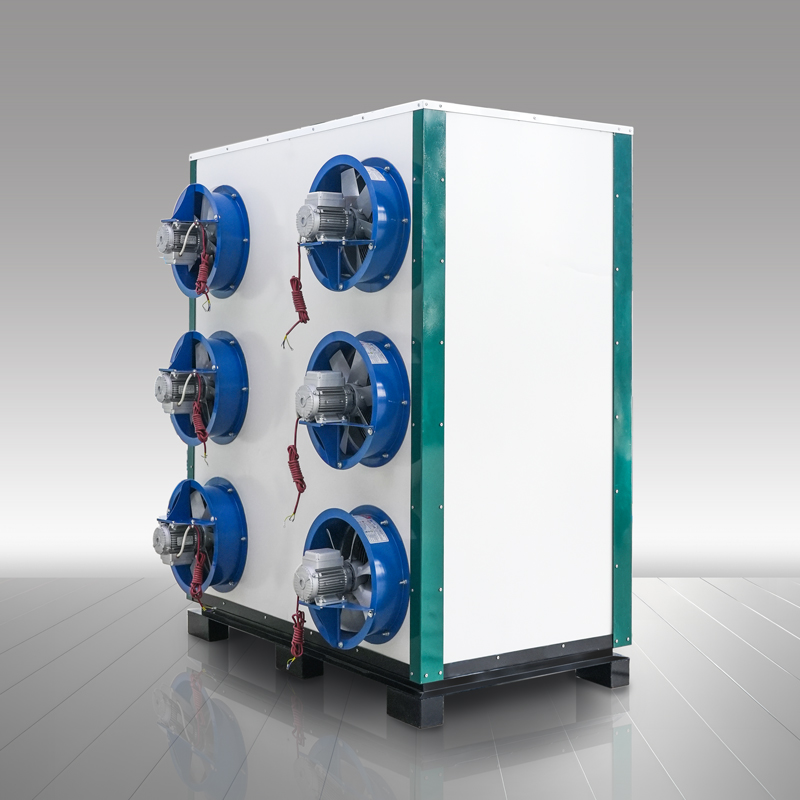

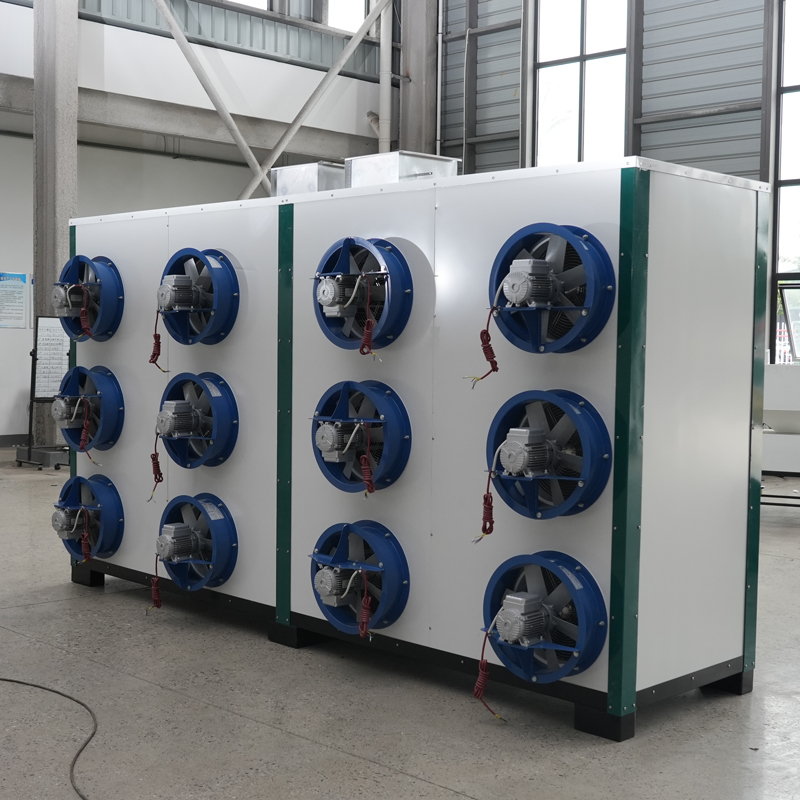

Real photo