WesternFlag – TL-5 Model Indirect Burning Furnace With 5 Layers Sleeve

Short description

TL-5 incinerator comprises 5 components: a fan, flue gas inducer, burner, five-layer casing, and control system. The flue gas circulates twice within the furnace, while fresh air circulates thrice. The burner ignites natural gas to produce a high-temperature flame. Guided by the flue gas inducer, heat is transferred to the warmed air through the five-layer casing and dense fins. Simultaneously, the flue gas is expelled from the unit once its temperature drops to 150℃. The heated fresh air enters the casing via the fan. Subsequently, after the heating process, the air’s temperature reaches the designated level and exits through the hot air outlet.

Advantages/Features

1. Uninterruptedly furnishing clean air at a constant pressure and temperature.

2. Wide adjustability in temperature: 40~300℃.

3. Automated operation that involves indirect heating, complying with exhaust gas emission standards.

4. Rational design, space-saving structure, achieving thermal efficiency of up to 75%.

5. Inner tank constructed from durable, high-temperature resistant stainless steel.

Specifications

| Model TL5 | Output heat (×104Kcal/h) |

Output temperature (℃) |

Output air volume (m³/h) |

Weight (KG) |

Dimension(mm) | Power (KW) |

Material | Heat exchange mode | Fuel | Atmospheric pressure | Traffic (NM3) |

Parts | Applications |

| TL5-10 Natural gas indirect burning furnace |

10 | Normal temperature to 350 | 3000--20000 | 1050KG | 2000*1300*1450mm | 4.2 | 1. High temperature resistant stainless steel for inner tank 2. Carbon steel for remaining four layers |

Direct combustion type | 1.Natural gas 2.Marsh gas 3.LNG 4.LPG |

3-6KPa | 18 | 1. 1 pcs burner2. 1 pcs induced draft fan3. 1 pcs blower4. 1 pcs furnace body5. 1 pcs electric control box | 1. Supporting drying room, dryer and drying bed.2, Vegetables, flowers and other planting greenhouses3, Chickens, ducks, pigs, cows and other brooding rooms4, workshop, shopping mall, mine heating5. Plastic spraying, sand blasting and spray booth6. Rapid hardening of concrete pavement7. And more |

| TL5-20 Natural gas indirect burning furnace |

20 | 1300KG | 2300*1400*1600mm | 5.2 | 30 | ||||||||

| TL5-30 Natural gas indirect burning furnace |

30 | 1900KG | 2700*1500*1700mm | 7.1 | 50 | ||||||||

| TL5-40 Natural gas indirect burning furnace |

40 | 2350KG | 2900*1600*1800mm | 9.2 | 65 | ||||||||

| TL5-50 Natural gas indirect burning furnace |

50 | 3060KG | 3200*1700*2000mm | 13.5 | 72 | ||||||||

| TL5-70 Natural gas indirect burning furnace |

70 | 3890KG | 3900*2000*2200mm | 18.5 | 110 | ||||||||

| TL5-100 Natural gas indirect burning furnace |

100 | 4780KG | 4500*2100*2300mm | 22 | 140 | ||||||||

| 100 And above can be customized. |

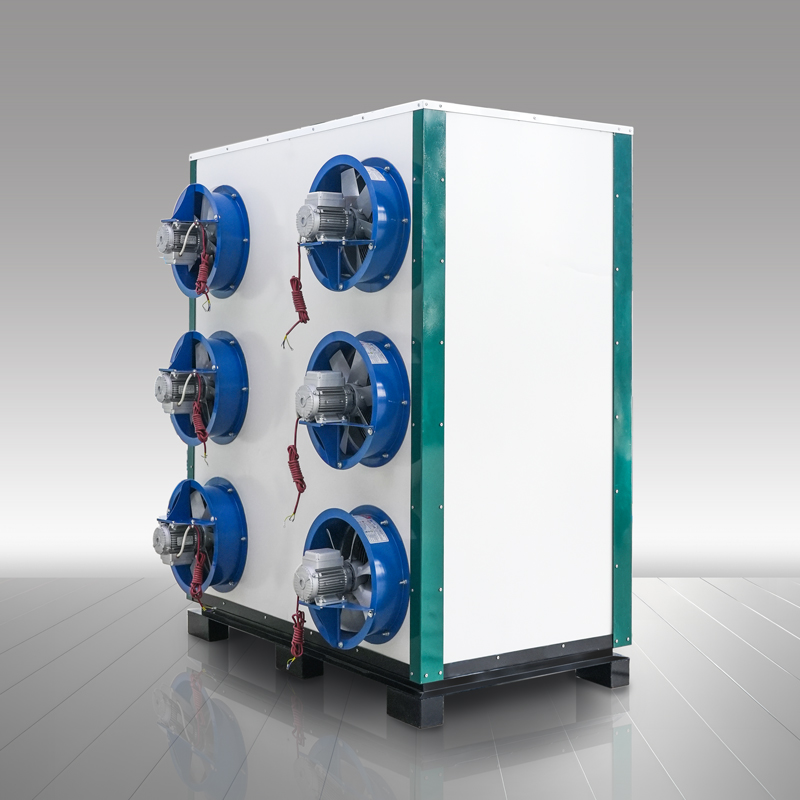

Real photo