WesternFlag – ZL-2 Model Steam Air Heater With Left-Right Circulation

Short description

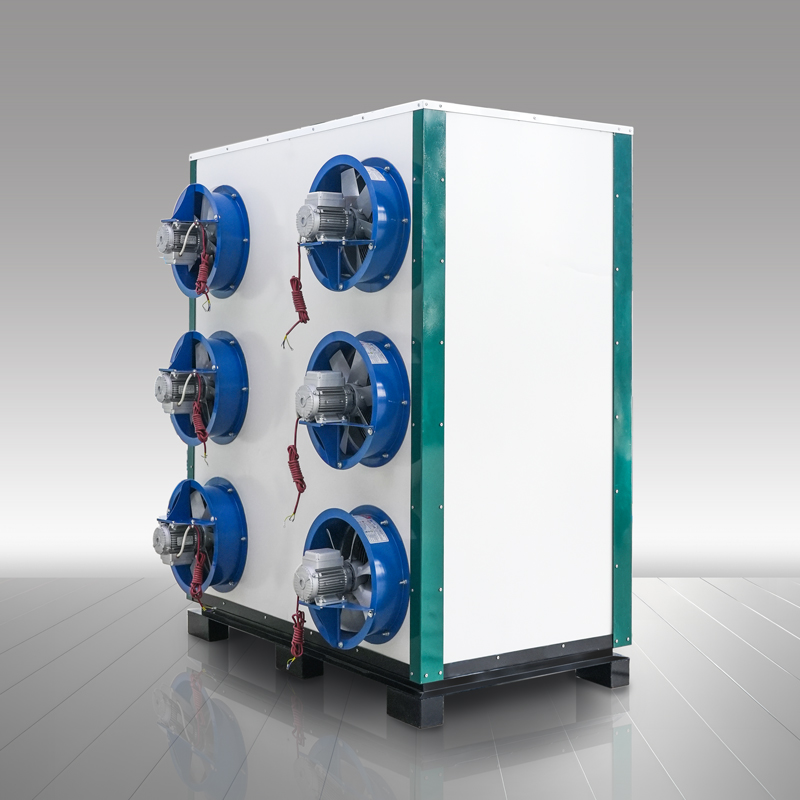

The ZL-2 steam air heater comprises seven components: radiant fin tube of steel and aluminum + electrical steam valve + overflow valve + heat isolation box + ventilator + Fresh air valve + electrical control system. It is particularly planned for supporting the left and right loop drying room. For instance, in the 100,000 kcal model drying room, there are 6 ventilators, three on the left and three on the right. When the three ventilators on the left rotate clockwise, the three ventilators on the right rotate counterclockwise in a cyclical consecutive manner, creating a relay. The left and right sides function as air outlets and inlets sequentially, removing all the heat produced by the steam heater. It comes with an electric fresh air valve to supplement fresh air together with the dehumidification system in the drying room/drying area.

Advantages/Features

1. Basic configuration and effortless installation.

2. Substantial air capacity and slight air temperature fluctuation.

3. Steel-aluminum finned tubes, exceptional heat exchange efficiency. The base tube is constructed of seamless tube 8163, which is immune to pressure and long-lasting.

4. Electrical steam valve regulates the intake, shutting off or opening automatically based on the established temperature, thereby precisely managing the temperature.

5. Dense fire-resistant rock wool insulation box to prevent heat loss.

6. Ventilator resistant to high temperatures and high humidity with an IP54 protection rating and H-class insulation rating.

7. Left and right ventilators run consecutively in cycles to ensure uniform heating.

8. Automatically supplement fresh air.

Specifications

| Model ZL2 (Left-right circulation) |

Output heat (×104Kcal/h) |

Output temperature (℃) |

Output air volume (m³/h) |

Weight (KG) |

Dimension (mm) |

Power (KW) |

Material | Heat exchange mode | Medium | Pressure | Flow (KG) |

Parts | Applications |

| ZL2-10 Steam direct heater |

10 | Normal temperature - 100 | 4000--20000 | 390 | 1160*1800*2000 | 3.4 | 1. 8163 seamless carbon steel pipe2. Aluminum heat exchange fins3. High-density fire-resistant rock wool for box4. Sheet metal parts are sprayed with plastic; remaining carbon steel5. Can be customized by your requirements | Tube + fin | 1. Steam2. Hot water3. heat transfer oil | ≤1.5MPa | 160 | 1. 1 set of electric valve + bypass2. 1 set of trap + bypass3. 1 set of Steam radiator4. 6-12 pcs circulating fans5. 1 pcs furnace body6. 1 pcs electric control box | 1. Supporting drying room, dryer and drying bed.2, Vegetables, Flowers and other planting greenhouses3, Chickens, ducks, pigs, cows and other brooding rooms4, workshop, shopping mall, mine heating5. Plastic spraying, sand blasting and spray booth6. And more |

| ZL2-20 Steam direct heater |

20 | 510 | 1160*2800*2000 | 6.7 | 320 | ||||||||

| ZL2-30 Steam direct heater |

30 | 590 | 1160*3800*2000 | 10 | 500 | ||||||||

| 40, 50, 70, 100 and above can be customized. |

Working Schematic Diagram

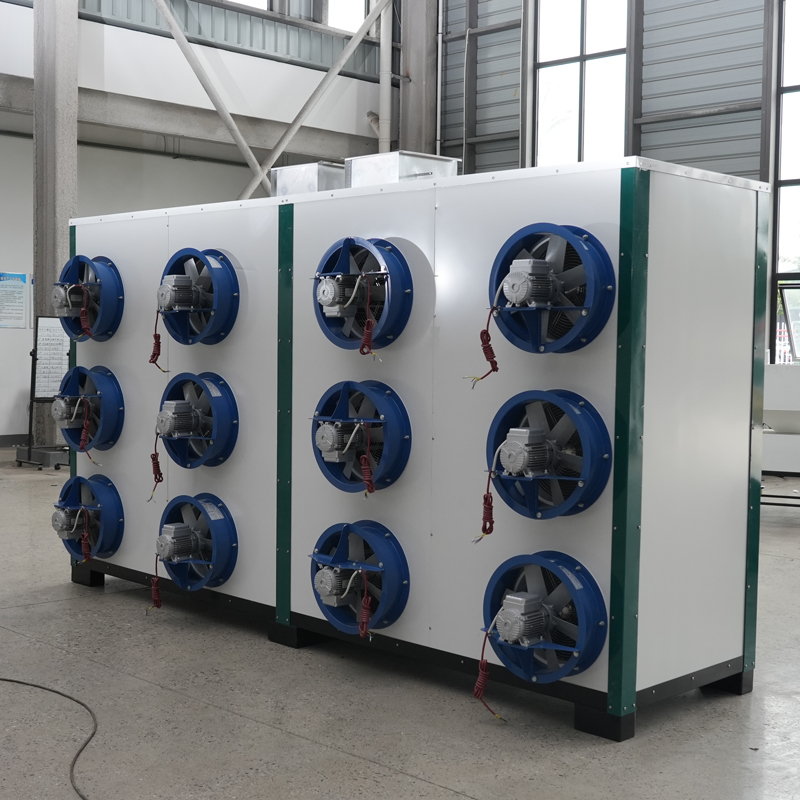

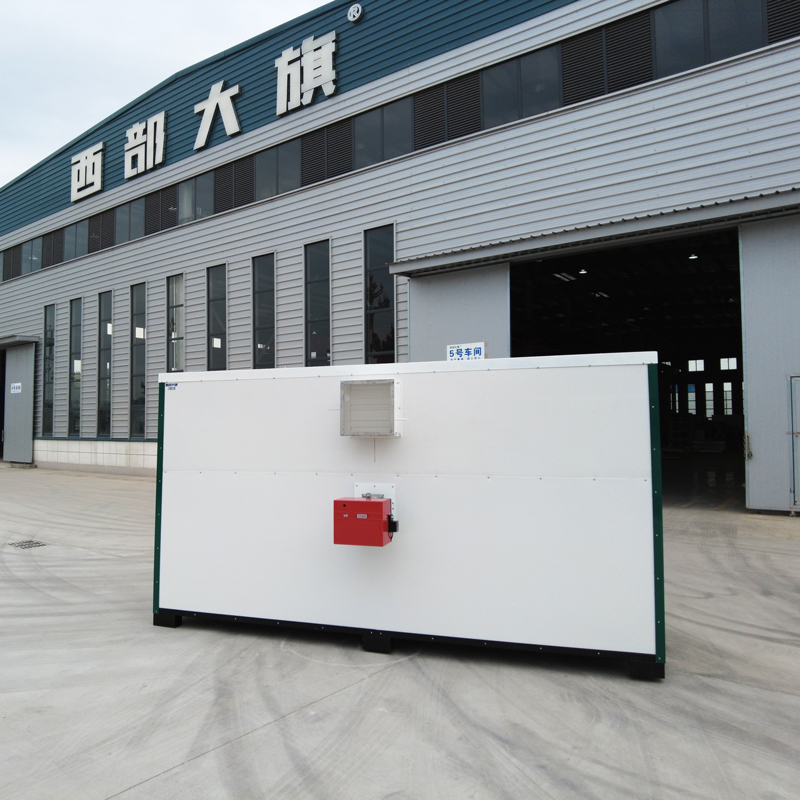

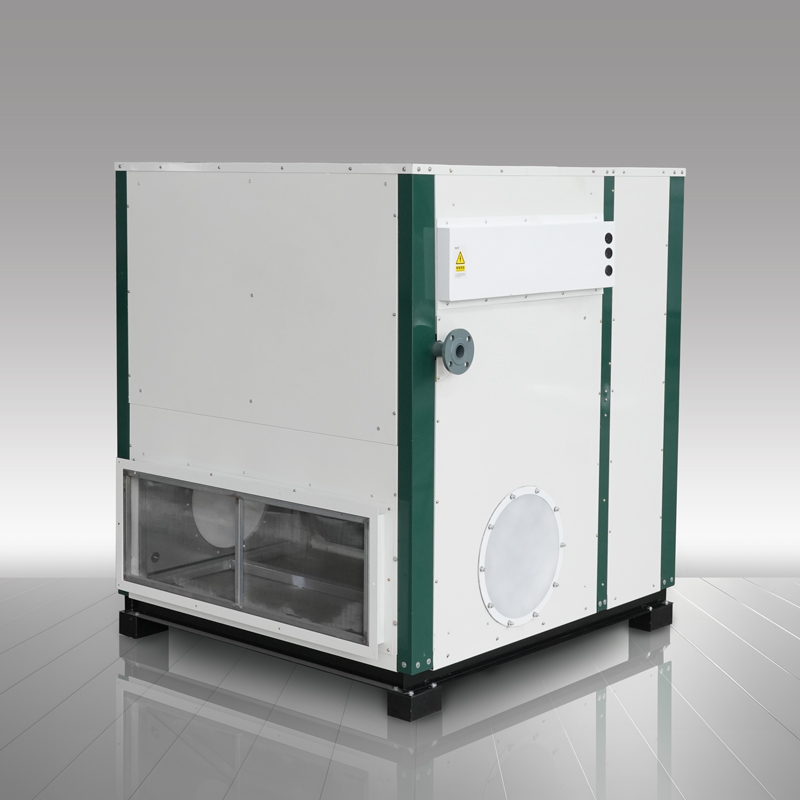

Real photo